Contact Us

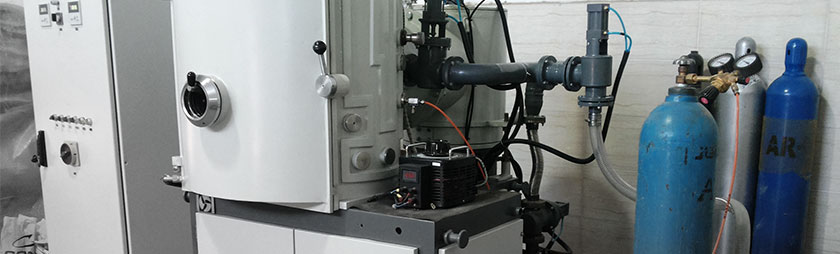

Plasma Nitriding, also referred to as ion nitriding, is a thermochemical treatment that improves the wear, corrosion resistance and fatigue properties of the product being nitrided. The process was developed in the early 1930’s as an alternative to the gas nitriding. It involves diffusion of nitrogen atoms into the metal surface in presence of a plasma environment. The plasma nitriding apparatus consists of a vacuum chamber which is connected to anode and a cathode, where the parts are placed. A nitriding atmosphere, consisting of a mixture of nitrogen and hydrogen gasses, is established at pressures that may vary from 1 to 10 mbar. The voltage applied between anode and cathode typically lies in the range of 300 to 800 volts. The applied potential ionises the gas mixture. The plasma generated by the ionization, envelops the surface of the workpiece with a blue-violet glow. The charged positive (nitrogen) ions are accelerated and hit the negatively charged workpieces with a relatively high level of kinetic energy. A large proportion of this (up to 90%) is then transferred to heat energy and thereby heats the workpiece to its required nitriding temperature.

Depending on the part, the treatment temperature is set between 400 °C and 570 °C. As a result, nitrogen is transferred to the workpiece, which then penetrates inside by diffusion, leading to the formation of a wear and corrosion resistant layer. This layer, which is called “white” or “compound” layer can consists of iron nitride phases, gamma prime, Fe4N, or epsilon, Fe2-3 N. Below the compound layer there is a diffusion layer or zone where the steel matrix is supersaturated by the in-diffusion of nitrogen atoms. The diffusion zone with its induced compressive residual stress, enhances fatigue strength of the workpiece. A typical treatment duration is between 5 up to 50 hours and depends on the chemical composition of the material used, the layer composition desired and the layer thickness required.

Advantages of plasma nitriding :

· Less treatment time. 33- 50% of other nitriding methods

· Low distortion and negligible dimensional changes

· Possibility of production of desired surface phases

· Homogenous treatment of parts with complex geometry

· Environmentally friendly

· Possibility of removing surface oxides and contaminations

· Less energy consumption in comparison to other nitriding methods

· Less gas consumption in comparison to other gas nitriding

· Improvement of mechanical properties of the parts

· High corrosion resistant surfaces

· Surface quality higher than with other nitriding methods (less roughness)

· High reproducibility of nitrided parts results with mass production

· Nitriding depth up to 0.8 mm

· All iron based materials can be treated

· No salt residues, therefore no salt removal expenses

Design And Seo By Mojrianweb