Contact Us

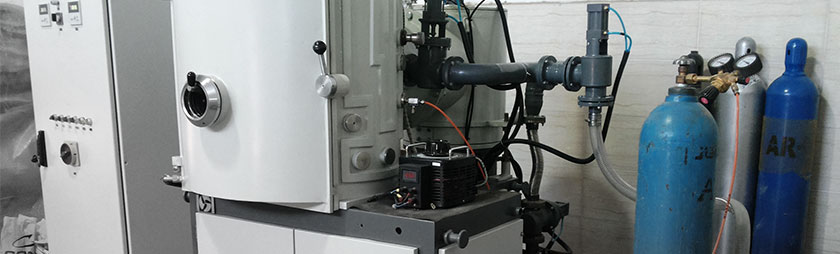

PACVD has been developed to combine the good adhesion of CVD and the low temperatures of PVD, while avoiding their typical shortcomings, high temperature with deformations and poor adhesion, respectively. The PACVD process is sometimes referred to PECVD where the “E” stands for “enhanced.”The process is used to deposit smooth, well adhered TiN, TiCN,

and similar hard coatings in a low vacuum environment at temperatures around 500°C, meaning a wide range of materials can be coated. It is characterized by a high throwing power and no solid target or cathode is used as is the case for the PVD process. Moreover, parts do not need to be rotated in the chamber. It is a clean, reliable and high technology coating process. PACVD process is capable of depositing coatings on a very broad range of substrates. Common applications include engine and machine components, pump parts, medical devices, dies, cutting tools and decorative items.

Plasma oxidation process produces a thin oxide layer on top of the compound layer, which can cover and seal micropores in the compound layer and further improves the corrosion resistance of nitrided or nitrocarburised steel components. The important factor at the plasma oxidation process is that the oxidation has to be controlled to avoid hematite (Fe2O3) formation and produce pure magnetite (Fe3O4) which is highly corrosion resistance.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s

Design And Seo By Mojrianweb