Contact Us

Plasma oxidation process produces a thin oxide layer on top of the compound layer, which can cover and seal micropores in the compound layer and further improves the corrosion resistance of nitrided or nitrocarburised steel components. The important factor at the plasma oxidation process is that the oxidation has to be controlled to avoid hematite (Fe2O3) formation and produce pure magnetite (Fe3O4) which is highly corrosion resistance.

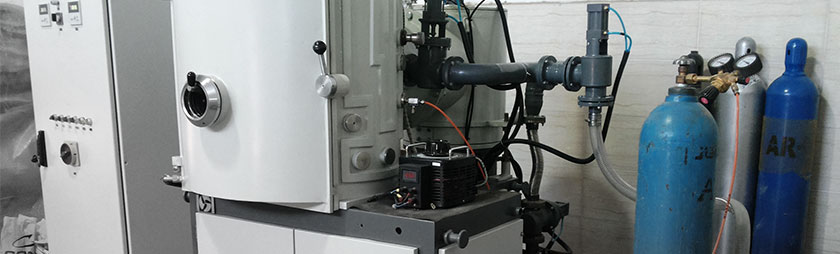

Undoubtedly, in any application where wear resistant along with dimensional stability and surface cleanliness are desirable, plasma surface treatments such as plasma nitriding or plasma assisted chemical vapor deposition (PACVD) techniques are amongst the best choices and in a number of applications such as some of airplane parts are the only option.

Design And Seo By Mojrianweb